We receive more questions about gold-filled items than any other products here at Halstead. This piece will focus on how to solder gold-filled jewelry items and the issues that may arise. We will also discuss other hot topics dealing with gold-filled items such as sanding, filing, and cleaning.

Before tackling how to work with gold-filled jewelry making supplies, it’s good to get a refresher on the raw material. Gold-filled is a layered product, where 12 or 14k gold is bonded on top of another material, usually jeweler’s brass. This means that it isn’t solid, and that layer of gold can wear off. For a deep dive into the material check out our blog What is Gold-Filled? Now we’ll dive into the complications you might have when fabricating gold-filled jewelry, tips to best work with it, and how to clean gold-filled jewelry.

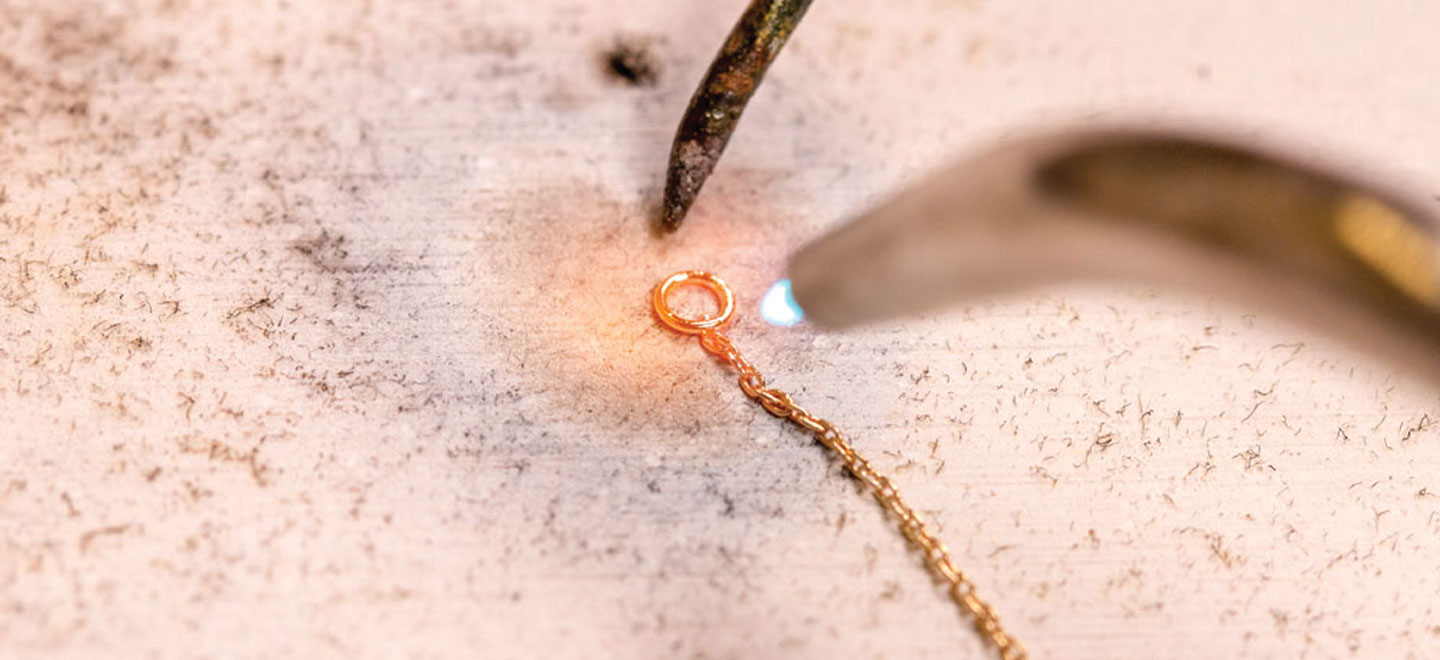

How Do You Solder Gold-Filled?

Gold-filled products are amazing, but now let's discuss the limitations when it comes to soldering gold-filled. Think about it; applying heat to a layered material can distort or mix the separate layers. Soldering gold-filled products should not be attempted without professional training and proper jewelry tools. There is no such thing as "gold-filled solder." Instead, use a color matched gold solder for 14k gold. That being said, it can be done! However, it does open up a couple of possible problems that you might experience.

Color Matching

One dilemma you'll run into is color matching your gold solder with your gold-filled piece. Since the surface layer of gold is usually 12 or 14 karat gold alloy, you should choose a solder that is color-matched to 14 karat gold. There is no such thing as gold-filled solder. 14kt gold alloys mostly consist of gold, silver, and copper. They also usually contain the metal zinc (with tin and indium mixed in depending on the solder type and vendor). The metals found in gold solder are important because they cause the solder to flow at a lower melting point than the material you are soldering. However, since the percentages of the copper and silver differ in the solder compared to the gold alloys, those amounts affect the colors.

Note: Depending on the karat of the solder, the alloys and the percentages will differ as well as the melt and flow points of the solder.

Alloying Layers

The biggest issue when you learn how to solder gold-filled products with a torch is that you can actually alloy the gold layer with the brass core. This leaves a dark, discolored solder join and any exposed brass would tarnish quicker than the surrounding metal in the piece of jewelry. This is an obvious quality problem for your customers. You want to heat your piece just to the point of solder flow between 1275-1450 degrees Fahrenheit. But, avoid overheating to the melting points of the 14 karat gold layer at 1550 degrees Fahrenheit and the brass core at roughly 1650 degrees Fahrenheit. If your gold surface layers start to melt and flow, you will have an irreversible problem.

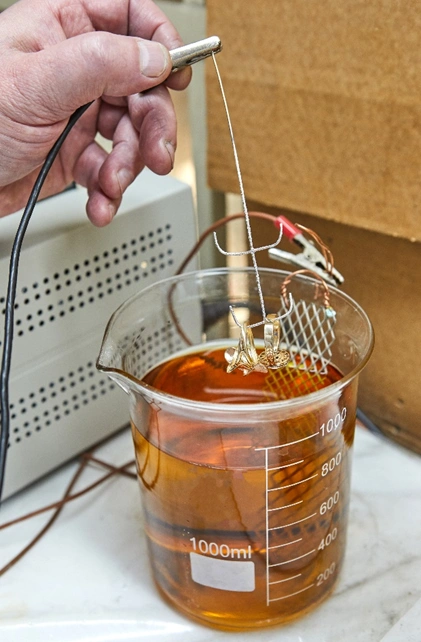

Adding a Plated Finish to Any Soldered Gold-Filled Items

If either the colors don't match or the brass has been exposed, the only way to fix it at this point is to gold-plate the entire piece. This will place a layer of gold across the entire surface creating a uniform color and protecting the exposed brass from tarnishing. Since plating wears through overtime, the jewelry piece may no longer be a lifetime product. Moreover, even if you don't notice discoloration at the solder join immediately, that point may discolor in time if the gold layer has been thinned out; so, plating to finish is always recommended on soldered gold-filled.

Note: Plating to finish a piece is always recommended on soldered gold-filled items.

Plating is an intense process that requires harsh chemicals, safe disposal, and safety training. Most jewelry studios do not have plating equipment in-house. Instead, this service is usually outsourced to a specialist job shop. There are jewelry plating companies located around the country. Usually, plating services are priced by the gram. You will need to add this additional expense into the pricing calculation for your finished item and consider the turnaround time on the plating outsourcing. For more information on plating, check out our blog Jewelry Plating: Why and How It’s Used.

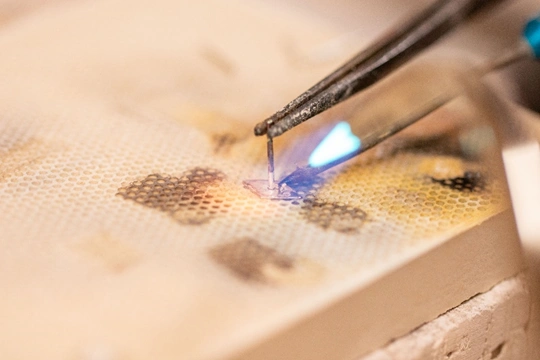

Laser and Pulse-Arc Welding

We have a variety of manufactured gold-filled chains and findings and many have solder joins. These solder joins are often done at the manufacturers using a laser welding machine, which leaves a precise solder joint. Most manufactured items with joints are plated to protect these areas. Laser welders can be very expensive, but you can also use a pulse-arc welder and it functions very much the same way. To help mitigate the melting of materials together when using welders, add filler wire. This means you’re adding solid 14k gold into the weld to cover the area where the brass and gold melt together. Also practice with the different settings on your equipment to prevent overheating the material and alloying the layers of metal. You may also need to use pen plating at the join to protect it from discoloration over time.

Because welding always alloys the layers together and there is a high possibility of such happening with solder, it might be best to consider alternative methods of connection. Gold-filled is ideal for assembly, stamping, and riveting. Just make sure to use solid gold wire or a contrasting material, like silver, for your rivet! If you choose to solder or weld, we encourage you to always add a plated finished for quality. Or, communicate clear expectations to your customers about discoloration issues and piece longevity.

Piercing and Drilling Gold-Filled

Soldering is not the only challenge when making gold-filled jewelry. When you pierce a gold-filled item you are exposing the jeweler's brass in the center of the hole that you have drilled. Over time that brass will tarnish and stand out. The only way to fix that exposed brass is to plate the entire piece. That solid gold plating can help keep the brass from tarnishing, however, it may not last long especially if the hole has a jump ring through it which will rub the plating down. This applies to the edges of a pierced item as well.

Sanding and Filing Gold-Filled

Don't do it! You should never sand or file a gold-filled wire or findings. Sanding and filing will remove surface metal. If you do this with a gold-filled item, you are removing the gold alloy layer. Removing that gold alloy changes the 5% total weight of your piece, so you can no longer legally call it gold-filled. Similarly, you should avoid diamond cutting, engraving or polishing with other abrasives. Even polishing cloths impregnated with abrasives for cleaning can thin your gold layer. Thinning the gold layer on the surface, will impact the durability of the material. The material is more likely to tarnish or discolor without the protective gold layer fully intact.

Can You Cast Gold-Filled?

Unfortunately, gold-filled items cannot be cast, so there is a limit on what jewelry findings are available. Casting requires the metals to be melted during the process, which would destroy the layered product so instead, sheet, tubing, and wire are used to manufacture gold-filled items. Gold-filled charms are usually die-formed out of thin sheet to get varied dimension. If you see something that looks cast, it’s likely only gold plated.

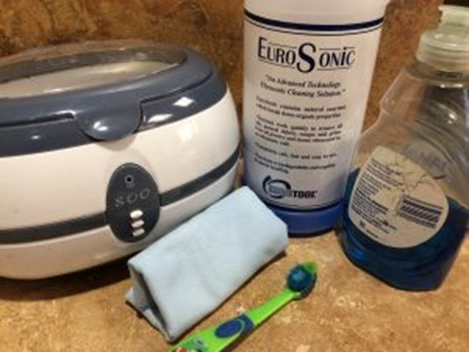

Polishing and Cleaning Gold-Filled

To remove fingerprints or grease from your gold-filled items, use a child's soft toothbrush with a mild soap. This quick polish should have it looking like new again but, you can also try ultrasonic baths and soft polishing cloths as long as the chemicals used are gold-filled friendly and the cloth is non-abrasive.

Download Gold-Filled Care and Cleaning Info Cards

These cards are formatted to fit on 2x3 business cards! Create a double-sided insert or add them to the back of your business card so your customers will always know how to care for their jewelry.

Gold-Filled Care & Cleaning Card

Gold-Filled 101 Video

In this video, Hilary Halstead-Scott discusses "what is gold-filled?", which includes gold alloys, gold-filled limitations, and the construction of gold-filled materials.

For more:

What is Gold-Filled? And More Common Questions

Jewelry Plating: Why and How It’s Used

How to Finish Gold-Filled Chain Jewelry

Questions & Answers

Q: Hi Erica, Thank you for the explanation. I bought some gold-filled ear studs recently (because I have a metal allergy, I, unfortunately, don't know against what, but gold and silver work fine). I reacted to the ear studs and when I took them out after a day, I noticed that the solder that connected the stud to the earring was discolored, now I'm wondering if that is exactly the problem described: That the inner metal was exposed there.

What do you think? I really want to get my money back because they were quite expensive, but I don't want to make false allegations. Thank you so much for your help! - Selina

A: Hi Selina, that's a great question without an easy answer. Yes, they could have alloyed the gold layer and the brass core, but it could also be an allergic reaction to the gold solder itself. Gold solder contains gold, silver, copper, zinc & tin (with gallium and indium also found in a few). You may very well be allergic to one of these metals. The discoloring is probably due to the difficulty of trying to match the gold solder with the gold-filled piece, not because the jeweler's brass has been exposed, however, it's tough to say without seeing it, though.

Hopefully, they have a return policy. Good luck!

Q: Really grateful for this article. It has been MY number one question since so many GF findings and wire have become available. Thanks for anticipating all my questions! - Tina

A: Thanks for the comment, Tina. Glad I could help!